Strong corrosion slurry filtration filter press

✧ Kugadzirisa

Isu tinokwanisa kugadzirisa mafineta zvinoenderana nezvinodiwa nevashandisi, senge rack inogona kuputirwa nesimbi isina tsvina, PP ndiro, Kupfapfaidza mapurasitiki, kune akakosha maindasitiri ane ngura yakasimba kana giredhi yechikafu, kana zvakakosha zvinodiwa zvemhando yekusefa doro senge kuvhuvhuta, muchetura, kunhuhwirira kunhuwa kana kupisa, nezvimwe. Welcome kutitumira zvaunoda zvakadzama.

Isu tinokwanisa zvakare kushongedza nepombi yekudyisa, bhandi rekutakura, mvura inogamuchira flap, sefa jira remvura yekugeza system, dope rekuchengetedza hopper, nezvimwe.

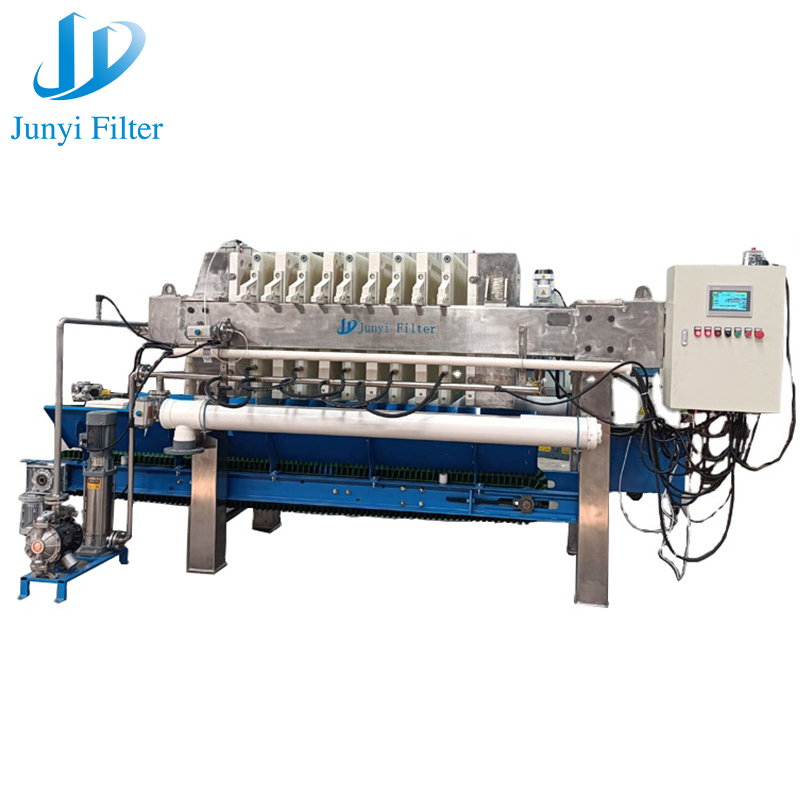

1. The Filter Press inopindirana ne rack, filter plate, filter cloth, hydraulic system uye magetsi emagetsi, nezvimwewo.

2. Zvinhu zveRack: Carbon steel, SS yakaputirwa, yakaputirwa PP, poda yehupfu.

3. Kudzvanya system: Manual jack pressing, hydraulic pressure automatic pressing.

4. Nyaya yeplate yefaira: PP plate, membrane plate, high pressure filter plate, high temperature filter plate, cast iron filter plate, SS filter plate.

✧ Product Features

A-1. Filtration pressure:0.6Mpa;1.0Mpa;1.3Mpa;1.6Mpa. (Sarudzo)

A-2. Diaphragm inosvina keke pressure:1.0Mpa;1.3Mpa;1.6Mpa. (Sarudzo)

B, filtration tembiricha:45 ℃ / kamuri tembiricha; 65-100 ℃/ tembiricha yepamusoro.(Zvichida)

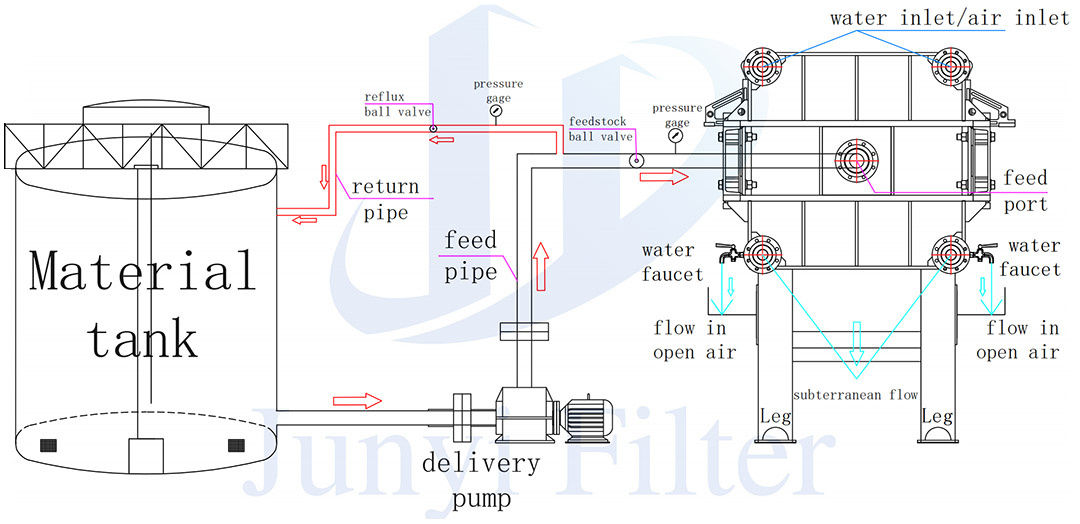

C-1. Discharge nzira - yakavhurika kuyerera:Mafauceti anoda kuiswa pazasi pekuruboshwe nekurudyi mativi ega ega refirita ndiro, uye singi inoenderana. Kuyerera kwakavhurika kunoshandiswa kune zvinwiwa zvisina kuwanikwa.

C-2. Liquid discharge nzira -kuvhara kuyerera:Pasi pekupedzisira kwechifukidzo chefivha, pane maviri epedyo anoyerera anobuda pombi huru, ayo akabatana neiyo mvura yekudzoreredza tank. Kana mvura yacho ichida kudzoserwa, kana kuti mvura yacho ichichinja, ichinhuwa, ichibvira moto uye ichiputika, kuyerera kwakasviba kunoshandiswa.

D-1. Kusarudzwa kwesefa jira zvinhu:Iyo PH yemvura inosarudza zvinhu zvejira resefa. PH1-5 ine acidic polyester sefa jira, PH8-14 is alkaline polypropylene sefa jira. Iyo viscous fluid kana yakasimba inosarudzwa kusarudza twill sefa jira, uye iyo isiri-viscous fluid kana yakasimba inosarudzwa plain filter jira.

D-2. Kusarudzwa kwesefa jira mesh:Iyo mvura inopatsanurwa, uye iyo inoenderana mesh nhamba inosarudzwa kune akasiyana akasimba particle size. Sefa jira mesh renji 100-1000 mesh. Micron kune mesh shanduko (1UM = 15,000 mesh---mupfungwa).

E. Rack surface treatment:Kana iyo PH ichikoshesa kwayakarerekera kana isina kusimba asidhi base: Kumusoro kwesefa yekutsikirira furemu kunotanga kuputiswa jecha, yozopfapfaidzwa nependi yeprimer uye anti-corrosion. Kana iyo PH kukosha kwakasimba asidhi kana alkaline yakasimba, pamusoro pesefa yekutsikirira furemu inoputirwa nejecha, yakapfapfaidzwa neprimer, uye iyo nzvimbo yakaputirwa nesimbi isina tsvina kana PP ndiro.

F. Diaphragm filter press operation(yekusarudza): Automatic Hydraulic Pressing; Sefa keke washing, Automatic Sefa Plate Kudhonza; Sefa Plate Vibrating Cake Discharge; Otomatiki Sefa Mucheka Rinsing System. Ndokumbira undiudze maficha aunoda usati wahodha.

G. Sefa kugeza keke (yekusarudza): Kana zvakaonda zvinoda kudzoserwa, keke resefa rine acidic yakasimba kana alkaline; Kana iyo keke yekusefa inoda kushambidzwa nemvura, ndapota tumira email kuti ubvunze nezve nzira yekugeza.

H. Sefa yekudyisa pombi(yekusarudza): Iyo yakasimba-mvura reshiyo, acidity, tembiricha uye maitiro emvura akasiyana, saka pombi dzekudyisa dzakasiyana dzinodiwa. Ndokumbira utumire email kuti ubvunze.

I. Otomatiki bhandi conveyor(yekusarudza): Bhandi rekutakura rinoiswa pasi peplate ye filter press, iyo inoshandiswa kutakura keke rakabudiswa mushure mokunge mahwendefa adhonzwa akazaruka. Ichi chishandiso chakakodzera purojekiti iyo isiri nyore kugadzira hwaro pasi. Inogona kuendesa keke kunzvimbo yakatarwa, iyo inoderedza basa rakawanda.

J. Otomatiki inodonha tireyi(yekusarudza): Drip tray inoiswa pasi peplate ye filter press. Munguva yekusefa, matireyi maviri eplate ari munzvimbo yakavharwa, iyo inogona kutungamira mvura inodonha panguva yekusefa uye jira rekugeza mvura kumuunganidzi wemvura parutivi. Mushure mekusefa, matireyi maviri eplate achavhurwa kuti abudise keke.

K. The filter press jira mvura flushing system(yekusarudza): Inoiswa pamusoro pedanda guru refivha yekusefa, uye yakashongedzerwa neatomatiki yekufambisa basa, uye jira resefa rinobva racheneswa nemvura yakakwira (36.0Mpa) nekuchinja vharafu. Kune marudzi maviri ezvivakwa zvekugezesa: rising-side rising uye kaviri-side rising, umo iyo kaviri-side rinsing ine mabhurashi ekuita zvakanaka kuchenesa. Iine flap mechanism, mvura yekusuka inogona kushandiswa zvakare uye kushandiswazve mushure mekurapa kuchengetedza zviwanikwa; yakasanganiswa ne diaphragm press system, inogona kuwana yakaderera mvura yemukati; yakaungana furemu, compact chimiro, nyore kupatsanura uye kutakura.

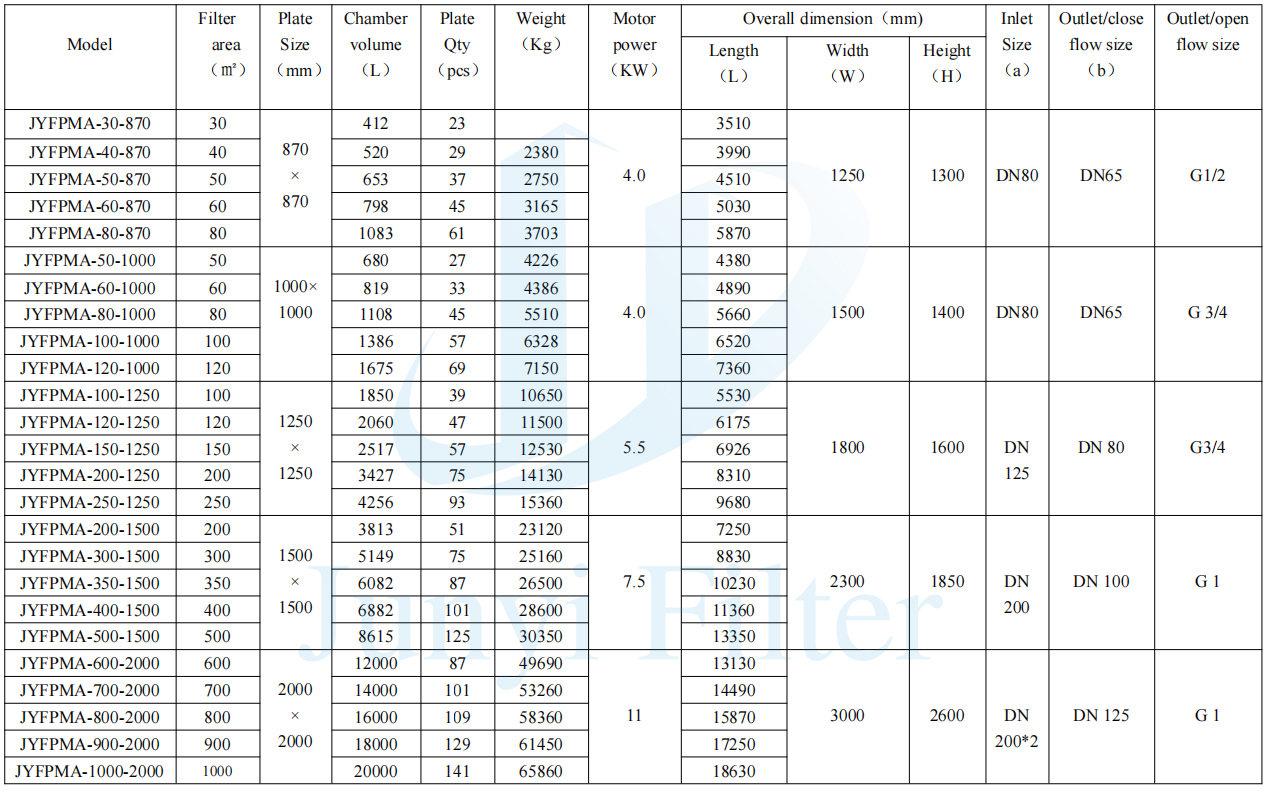

| Sefa Press Model Guidance | |||||

| Zita remvura ? | Solid-liquid ratio (%) ? | Chaiyo gravity yezvakaoma ? | Material status ? | PH kukosha ? | Solid particle size (mesh) ? |

| Tembiricha (℃) ? | Kudzoreredzwa kwezvinwiwa/zvakaoma ? | Mvura yemukati yemusefa keke ? | Maawa ekushanda/zuva ? | Kugona/zuva ? | Ingave mvura inoputika kana kwete ? |

✧ Kudyisa Maitiro

✧ Sefa Dzvanya Kuodha Mirayiridzo

1. Tarisa kune dhizaini yekusarudza dhizaini, sefa yekuona pamusoro, zvakatemwa uye modhi, sarudzaiyo modhi nemidziyo inotsigira zvinoenderana nezvinodiwa.

Semuenzaniso: Kunyangwe keke resefa rakagezwa kana kuti kwete, ingave iyo filtrate yakavhurika kuyerera kana kuyerera kwekuvhara,ingave iyo rack isingadziviriri kana kwete, maitiro ekushanda, nezvimwe.

2. Maererano nezvinodiwa zvakakosha zvevatengi, kambani yedu inogona kugadzira uye kugadziranon-standard modhi kana customized zvigadzirwa.

3. Mifananidzo yechigadzirwa yakapihwa mugwaro iri ndeyekungotaura chete. Kana pane shanduko, isuhaizopa chiziviso chipi nechipi uye kurongeka chaikoiko kuchatonga.

✧ Otomatiki Diaphragm Sefa Dhinda